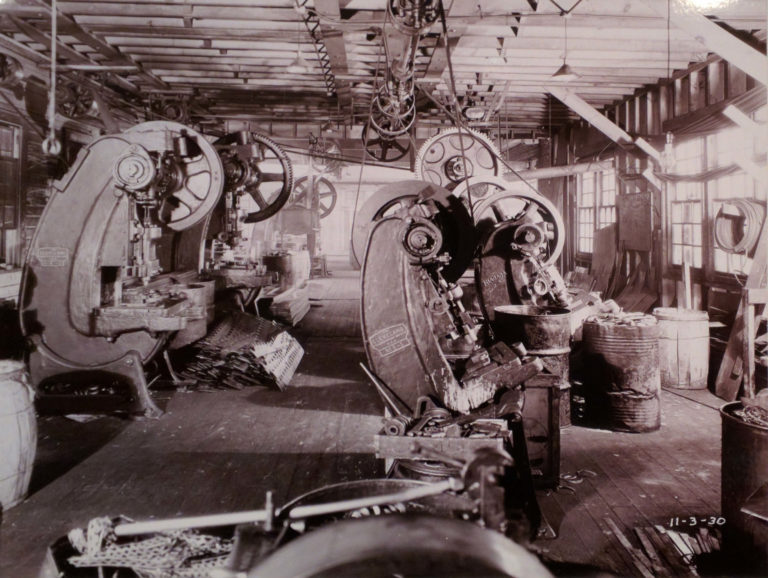

We are dedicated to providing metal formed products that exceed all expectations. This requires our commitment to constant improvement. Through technology and innovation, we continuously develop manufacturing solutions that help drive our customers’ success within various markets. For nearly a century, we are proud to contribute towards the advancement of many industries and we are excited to support the needs of the future.